In medical practice, cleaning and disinfection of anesthesia machines is an important part of ensuring surgical safety and preventing hospital-acquired infections. In particular, the internal circuit of anesthesia machines, which is directly connected to the patient's respiratory system, is particularly important for disinfection.

1.Anesthesia machine contamination status

At present, although the operating rooms of various hospitals are equipped with advanced laminar flow purification and surface disinfection systems to ensure that the indoor environment meets the standards, the anesthesia machine is difficult to completely disassemble and disinfect due to its complex structure and precise components, and laminar flow purification is difficult to penetrate its internal pipes. Although disposable anesthesia breathing circuits, anesthesia masks, and heat and moisture exchangers are widely used to reduce the risk of infection, the problem of bacterial contamination in the internal pipes of anesthesia machines is still serious, especially the exhalation check valve, exhalation port, soda lime tube inlet and the inside of the bellows, which have become areas with high bacterial positive rates. Therefore, disinfection of the internal circuit of the anesthesia machine plays an important role in reducing the incidence of nosocomial infections.

2.Anesthesia machine disinfection steps

(I) Preparation before disinfection

1. Personal protection: Wear a mask, gloves, and protective clothing and goggles when necessary to ensure personal safety and prevent the disinfectant from damaging the skin.

2. Turn off the power and disconnect: Make sure the anesthesia machine is completely turned off, and unplug the power plug and all trachea connected to the patient or gas supply source.

3. Prepare disinfection supplies: According to hospital regulations and the material of the anesthesia machine, select appropriate disinfectants (such as chlorine-containing disinfectants, peracetic acid, compound alcohol disinfectants, etc.), cleaning cloths, disinfectant containers, and necessary disinfection tools (such as disinfection machines, brushes, spray bottles, etc.).

(II) External disinfection

Although the focus is on internal circuit disinfection, external disinfection should not be ignored. Use a wet cloth or sprayer to evenly spray an appropriate amount of disinfectant on the external surface of the anesthesia machine, and then wipe it clean with a clean cloth. Be careful to prevent the disinfectant from seeping into the machine or contacting electronic components.

3. Internal circuit disinfection

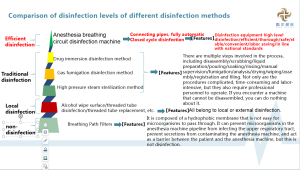

Traditional disinfection method

1. Disassemble the internal circuit: First, carefully disassemble the internal circuit according to the design of the anesthesia machine, including the breathing tube, breathing bag, filter and other components.

2. Preliminary cleaning: Place the disassembled parts in the cleaning tank and use running water or mild detergent for preliminary cleaning to remove surface dirt and residues.

3. Disinfection: Select an appropriate disinfection method.

Note:

(1) All parts can be sterilized with ethylene oxide;

(2) It is recommended to sterilize parts that are resistant to high temperature, high pressure and humidity with high pressure steam;

(3) The immersion time of synthetic rubber parts should not exceed 15 minutes to avoid swelling or accelerated aging;

(4) Do not immerse the circuit oxygen sensor or flow sensor in liquid;

(5) Do not sterilize the circuit oxygen sensor or plastic flow sensor under high temperature and high pressure conditions.

4. Drying: After the disinfection time is over, the parts need to be thoroughly rinsed with clean water to remove the residual disinfectant by drug immersion, and then gently wiped dry with a clean cloth, or placed in a clean and ventilated place to naturally dry and decompose the residue. After disinfection by ethylene oxide gas fumigation, it needs to be placed in a clean and ventilated place for 7 days until the ethylene oxide evaporates before it can be used.

5. Reassembly and testing: The disinfected and dried parts are reassembled on the anesthesia machine according to the original position and connection method. Perform a functional test on the anesthesia machine to ensure that all parts are working properly without leakage, blockage and other abnormal conditions.

Highly effective disinfection method (recommended)

At present, the recommended way to disinfect the internal pipelines of an anesthesia machine is to use an anesthesia machine respiratory circuit sterilizer for disinfection. It is easy to operate, does not need to disassemble the anesthesia machine during use, disinfects quickly, and uses a non-toxic and easily decomposable disinfectant (hydrogen peroxide). + ozone, complex alcohol + ozone, etc.) for disinfection. Relevant literature shows that after using the disinfection machine, the bacterial positive rate of the internal pipeline of the anesthesia machine and the postoperative respiratory tract infection rate of patients are significantly lower than when using traditional disinfection methods.