In the realm of medical instrument sterilization, the quest for effective and safe methods is an ongoing endeavor. One such method that has gained attention in recent years is hydrogen peroxide sterilization, often referred to as vaporized hydrogen peroxide (VHP) sterilization. This article delves into the intricacies of hydrogen peroxide sterilization and explores its potential as a viable option for sterilizing surgical instruments.

Understanding Hydrogen Peroxide Sterilization

Hydrogen Peroxide Sterilization, also known as Hydrogen Peroxide Gas Sterilization, is a low-temperature sterilization process primarily employed for heat-sensitive medical devices. Unlike conventional methods such as steam sterilization, hydrogen peroxide sterilization utilizes H2O2 vapor to sterilize exposed device surfaces, making it an attractive option for instruments that can't withstand high temperatures. This process is known for its efficiency and speed, often requiring less time compared to other sterilization techniques.

Low Temperature Sterilization

Low-temperature sterilization is essential for preserving the integrity of heat-sensitive devices. Alongside hydrogen peroxide sterilization, ethylene oxide (EO) sterilization is another commonly used method. While heat-stable instruments are compatible with various sterilization techniques, moisture and heat-sensitive devices necessitate specialized processes.

Vaporized Hydrogen Peroxide Sterilization

Healthcare facilities increasingly favor vaporized hydrogen peroxide sterilization over ethylene oxide due to several advantages. Hydrogen peroxide's household familiarity instills confidence in its non-toxic and environmentally friendly nature. Unlike ethylene oxide, VHP does not require additional utilities like water, steam, or compressed air, simplifying its implementation.

The Hydrogen Peroxide Sterilization Process

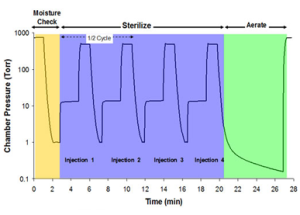

The sterilization process using vaporized hydrogen peroxide follows these steps:

-

- Liquid H2O2 Conversion: Liquid hydrogen peroxide is converted into vapor.

- Chamber Filling: The vapor fills the sterilization chamber, ensuring contact with all surfaces, including penetrating lumens.

- Sterilization Complete: After sterilization, the vapor is vacuumed from the chamber and converted into water and oxygen.

Safety and Guidelines

Both the Food and Drug Administration (FDA) and the International Organization for Standardization (ISO) have stringent requirements for sterilizers, including vaporized hydrogen peroxide sterilizers. These guidelines ensure:

-

- Patient Safety: Sterilizers must eliminate toxic residues from devices, ensuring patient safety.

- Device Compatibility: Hydrogen peroxide is known for its compatibility with various materials, safeguarding the integrity of medical instruments.

- Staff Protection: Strict guidelines exist for hydrogen peroxide exposure to protect Sterile Processing Department staff.

- Environmental Safety: VHP sterilization's by-products, water and oxygen, pose no harm to the environment.

Challenges of Hydrogen Peroxide Sterilization

While hydrogen peroxide sterilization offers numerous advantages, it comes with its set of challenges:

-

- Chamber Size: The sterilization chamber is typically smaller than that of steam sterilizers, limiting the quantity of instruments that can be processed simultaneously.

- Device Limitations: Sterilization cycles have specific limitations based on device design and manufacturer validation, requiring careful consideration.

- Device Compatibility: Not all heat and moisture-sensitive devices are validated or compatible with all VHP sterilizers, necessitating thorough device validations.

- Pre-processing: Adequate pre-processing of devices, including cleaning, drying, and wrapping, is essential for successful sterilization.

Conclusion

In the quest for effective and safe sterilization methods for surgical instruments, hydrogen peroxide sterilization has emerged as a compelling option. Its ability to sterilize heat-sensitive devices efficiently, along with its safety and environmental benefits, make it a viable choice for healthcare facilities. However, understanding the process, adhering to guidelines, and addressing its challenges are crucial for harnessing the full potential of hydrogen peroxide sterilization in the medical field.