In the process of ventilator disinfection, the anesthesia breathing circuit disinfection machine is often used as a professional disinfection equipment.

Ventilator disinfection is a vital task for medical institutions, which is directly related to the health and safety of patients. Ventilator disinfection mainly refers to the thorough cleaning and disinfection of the entire airway system of the ventilator, including the external pipes and accessories of the ventilator, the internal pipes and the surface of the machine. This process must be carried out strictly in accordance with the ventilator manual and relevant disinfection specifications to ensure the safety and effectiveness of the ventilator.

1.External disinfection

The outer shell and panel of the ventilator are the parts that patients and medical staff touch most frequently on a daily basis, so they must be cleaned and disinfected 1 to 2 times a day. When cleaning, use special medical disinfectant wipes or disinfectants that meet the requirements, such as disinfectants containing 500 mg/L of effective chlorine, 75% alcohol, etc., to ensure that there are no stains, blood stains, or dust on the surface. During the disinfection process, special attention should be paid to prevent liquids from penetrating into the machine to avoid causing circuit short circuits or machine damage.

2.Pipeline disinfection

The external pipes and accessories of the ventilator are directly connected to the patient's respiratory system, and their cleaning and disinfection are particularly important. According to WS/T 509-2016 "Specifications for the Prevention and Control of Hospital Infections in Intensive Care Units", these pipes and accessories should be "disinfected or sterilized for each person", ensuring that each patient uses strictly disinfected pipes. For patients who use it for a long time, new pipes and accessories should be replaced every week to reduce the risk of infection.

For the disinfection of the internal pipes of the ventilator, due to its complex structure and the involvement of precision parts. And the internal pipe structures of ventilators of different brands and models may be different, so the correct disinfection method and disinfectant must be selected to avoid damaging the ventilator or affecting its performance.

3.Anesthesia breathing circuit disinfection machine is recommended

The E-360 series anesthesia breathing circuit disinfection machine uses a high-frequency atomization device to atomize a specific concentration of disinfectant to produce a high-concentration small molecule disinfection factor, and then selects a microcomputer to control and start the O₃ generating device to produce a specific concentration of O₃ gas, and then transmits it through the pipeline to introduce it into the interior of the ventilator for circulation and disinfection, thus forming a safe closed loop.

It can effectively kill various harmful bacteria such as "spores, bacterial propagules, viruses, fungi, protozoan spores", cut off the source of infection, and achieve a high level of disinfection effect. After disinfection, the residual gas is automatically adsorbed, isolated and degraded by the air filter device.

The YE-360 series anesthesia breathing circuit disinfection machine uses a composite disinfection factor for comprehensive disinfection. This disinfection can fundamentally cut off medical-induced infections caused by repeated use of instruments and human contact, and has a high level of disinfection effect.

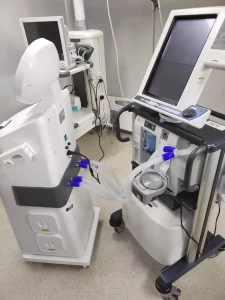

Anesthesia breathing circuit disinfection machine is disinfecting the ventilator

4.Product advantages

You only need to connect the pipeline to perform fully automatic closed-loop disinfection without disassembling the machine.

The dual-path dual-loop path cabin can be used to implant equipment accessories for cyclic disinfection.

Equipped with a smart chip, one-button start, simple operation.

Microcomputer control, atomization, ozone, adsorption filtration, printing and other components do not interfere with each other and are durable.

Real-time detection of concentration and temperature changes, and dynamic display of concentration and temperature change values, disinfection without corrosion, safety and guaranteed.

Anesthesia breathing circuit disinfection machines are of great significance in the disinfection of ventilators. As an indispensable device in intensive care and anesthesia, ventilators are often used to support and maintain patients' respiratory function. However, due to its direct contact with patients, it is very easy to become a medium for the spread of bacteria, viruses and other pathogens, leading to an increased risk of hospital-acquired infections. Anesthesia breathing circuit disinfection machines effectively kill various pathogens in the breathing circuit through professional disinfection procedures to ensure the safe use of ventilators.

Professional disinfection of ventilators can not only prevent cross-infection and ensure the safety of patients, but also extend the service life of the equipment and improve the quality of medical services. Therefore, anesthesia breathing circuit disinfection machines play a vital role in clinical practice.