In the medical field, the sterilization of surgical instruments is a fundamental practice to ensure patient safety and prevent the spread of infections. Hospitals and healthcare facilities rely on various sterilization methods, each with its own advantages and disadvantages.

Introduction to Sterilization Methods

Sterilization is the process of eliminating all forms of microbial life, including bacteria, viruses, fungi, and spores, from surgical instruments to prevent contamination during medical procedures. Several methods are commonly employed for sterilization:

1. Autoclaving:

Autoclaving is a widely used method that involves exposing instruments to high-pressure steam at elevated temperatures. It effectively kills microorganisms and spores.

Advantages: Relatively quick, reliable, and widely accepted.

Disadvantages: May not be suitable for heat-sensitive instruments.

2. Ethylene Oxide (EO) Sterilization:

EO sterilization is a low-temperature method that uses ethylene oxide gas to kill microorganisms. It is suitable for heat-sensitive items.

Advantages: Compatible with various materials, effective for a wide range of instruments.

Disadvantages: Longer cycle times, potentially hazardous gas.

3. Hydrogen Peroxide Vapor (HPV) Sterilization:

HPV sterilization uses hydrogen peroxide vapor to disinfect instruments. It is a low-temperature method and is considered environmentally safe.

Advantages: Quick cycles, compatibility with various materials, and no toxic residues.

Disadvantages: Limited chamber size.

4. Plasma Sterilization:

Plasma sterilization involves the use of a low-temperature plasma to kill microorganisms. It is suitable for delicate and heat-sensitive instruments.

Advantages: Effective for complex instruments, no toxic residues.

Disadvantages: Longer cycle times, specialized equipment required.

5. Dry Heat Sterilization:

Dry heat sterilization relies on hot air to sterilize instruments. It is suitable for items that can withstand high temperatures.

Advantages: Effective for certain instruments, no moisture-related issues.

Disadvantages: Longer cycle times, limited material compatibility.

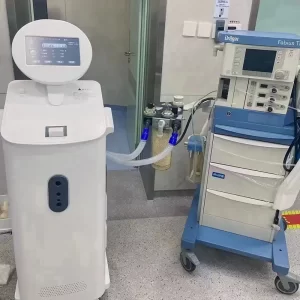

6、The Innovative Solution: Anesthesia Breathing Circuit Disinfection Machine

While the above methods are effective, they may require time-consuming processes and specialized equipment. However, there is an innovative solution that offers rapid and hassle-free instrument sterilization: the Anesthesia Breathing Circuit Disinfection Machine.

Key Features:

One-Step Disinfection: This machine simplifies the sterilization process by providing a one-touch solution. Simply connect the external threaded tube, and the machine takes care of the rest.

Rapid Cycle: The Anesthesia Breathing Circuit Disinfection Machine offers quick cycle times, ensuring that instruments are ready for use in minimal time.

Highly Effective: It provides high-level disinfection, effectively eliminating microorganisms and ensuring the safety of surgical instruments.

User-Friendly: The machine is designed for ease of use, making it suitable for healthcare professionals at all levels.

Conclusion

Sterilizing surgical instruments is a critical practice in healthcare settings. While various sterilization methods are available, each with its advantages and drawbacks, the Anesthesia Breathing Circuit Disinfection Machine stands out as an innovative solution for rapid and effective instrument sterilization. Its one-step disinfection process and quick cycle times make it a valuable addition to healthcare facilities, ensuring the highest standards of patient safety.