The growth and spread of internal germs has become a major issue in the use of sleep apnea machines and continuous positive airway pressure machines. Due to structural and design factors, temperature factors, the large amount of food provided to germs, and the rapid reproduction rate of germs, the interior of these devices can easily become a breeding ground for germs.

Reasons why sleep apnea machines and continuous positive pressure ventilators produce a large number of germs

1. Bacterial reproduction caused by structural and design factors-in order to minimize noise, a large amount of non-cleanable sound insulation cotton is wrapped around the fan. In order to prevent a large amount of dust from directly entering the airway and protect the fan, there are a large number of filter cottons in the air inlet channel. In order to be smaller and lighter, most machines do not separate the air path and the circuit, and germs can easily land on the warm circuit board and fan blades.

2. Bacterial reproduction caused by temperature factors-providing the best temperature zone for germ reproduction (5℃-20℃), the machine will heat up after working for a long time before stopping, and the internal protective layer will cause poor heat dissipation.

3. Providing a large amount of food for germs leads to bacterial reproduction-all filter cotton can only filter large particles of dust but not bacteria. On the contrary, it cannot clean the dust that accumulates in large quantities to provide energy and reproduction for bacteria.

4. Reproduction speed-according to microbiology, if the above conditions are met, the number of germs will increase by 1 million times within 16 hours (about doubling every 15 to 45 minutes).

Ventilator disinfection

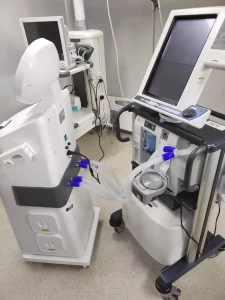

To this end, we need to choose professional medical equipment with effective disinfection capabilities, and the anesthesia breathing circuit disinfector can be a good assistant for us to disinfect anesthesia machines and ventilators.

Advantages of anesthesia breathing circuit disinfector:

High efficiency: The anesthesia breathing circuit disinfector has high disinfection performance and can complete the disinfection process in a short time. Only need to connect the external pipeline to disinfect the internal circuit, which can improve work efficiency, save time, and ensure the effective disinfection of the internal circuit of the anesthesia machine ventilator.

Easy to operate: The product is simple in design and easy to operate. Users only need to follow the instructions to complete the disinfection process. At the same time, the anesthesia breathing circuit disinfector is also equipped with corresponding preventive measures to prevent secondary contamination after use.

Anesthesia breathing circuit disinfection machine

Understanding the internal structure and construction of ventilators is crucial for ensuring effective disinfection and preventing cross-infection. Ventilators typically comprise components such as air filtration systems, humidifiers, sensors, valves, and tubing. These components work together to provide stable airflow and appropriate humidity levels to support the patient's respiratory function. The air filtration system filters out bacteria and particulates, keeping the air clean; the humidifier regulates air humidity to prevent the patient's respiratory tract from drying out; sensors monitor gas flow and pressure to ensure the ventilator operates correctly; valves and tubing transport and regulate airflow.

When using disinfection equipment, a comprehensive understanding of these internal structures ensures that every critical component is thoroughly disinfected. For example, the air filtration system and humidifier are areas where bacteria and viruses can easily accumulate, requiring special attention during disinfection. Precision components such as sensors and valves need careful handling to avoid damage, ensuring that disinfectants are used according to the manufacturer's specifications. Additionally, understanding the tubing and airflow pathways can help determine the circulation method of the disinfectant, ensuring that all internal surfaces are covered for complete disinfection.

In summary, a thorough understanding of the ventilator's internal structure not only enhances the effectiveness of disinfection but also extends the equipment's lifespan by avoiding damage from improper disinfection methods. By using scientific and reasonable disinfection methods, cross-infection can be effectively prevented, ensuring the safety of both patients and healthcare workers.